The need to use insulation materials in construction is indisputable. Thermal insulation makes sense both economically and ecologically. Ultimately, the energy saving that is produced also benefits the environment. However, there are a lot of assumptions about EPS which wrongly classify this material as being less eco-friendly. In actual fact, the opposite is true.

Since 1994, EPS has had a comprehensive “life cycle assessment” which considers all aspects from product manufacture through to disposal of waste materials and delivers an outstanding verdict in comparison to other insulation materials.

| Insulation material | flapor (EPS) | Sheep’s wool | Mineral wool | Wood fiber |

|---|---|---|---|---|

| Weight | ++ | ++ | -- | -- |

| Value for money | ++ | -- | - | -- |

| Processing | ++ | + | -- | - |

| Recyclability | ++ | + | -- | + |

| Fire behavior | -(0) | -(0) | ++ | -(0) |

| Lambda value (Thermal insulation performance) | ++ | - | + | - |

| Water absorption when damp | ++ | -- | - | - |

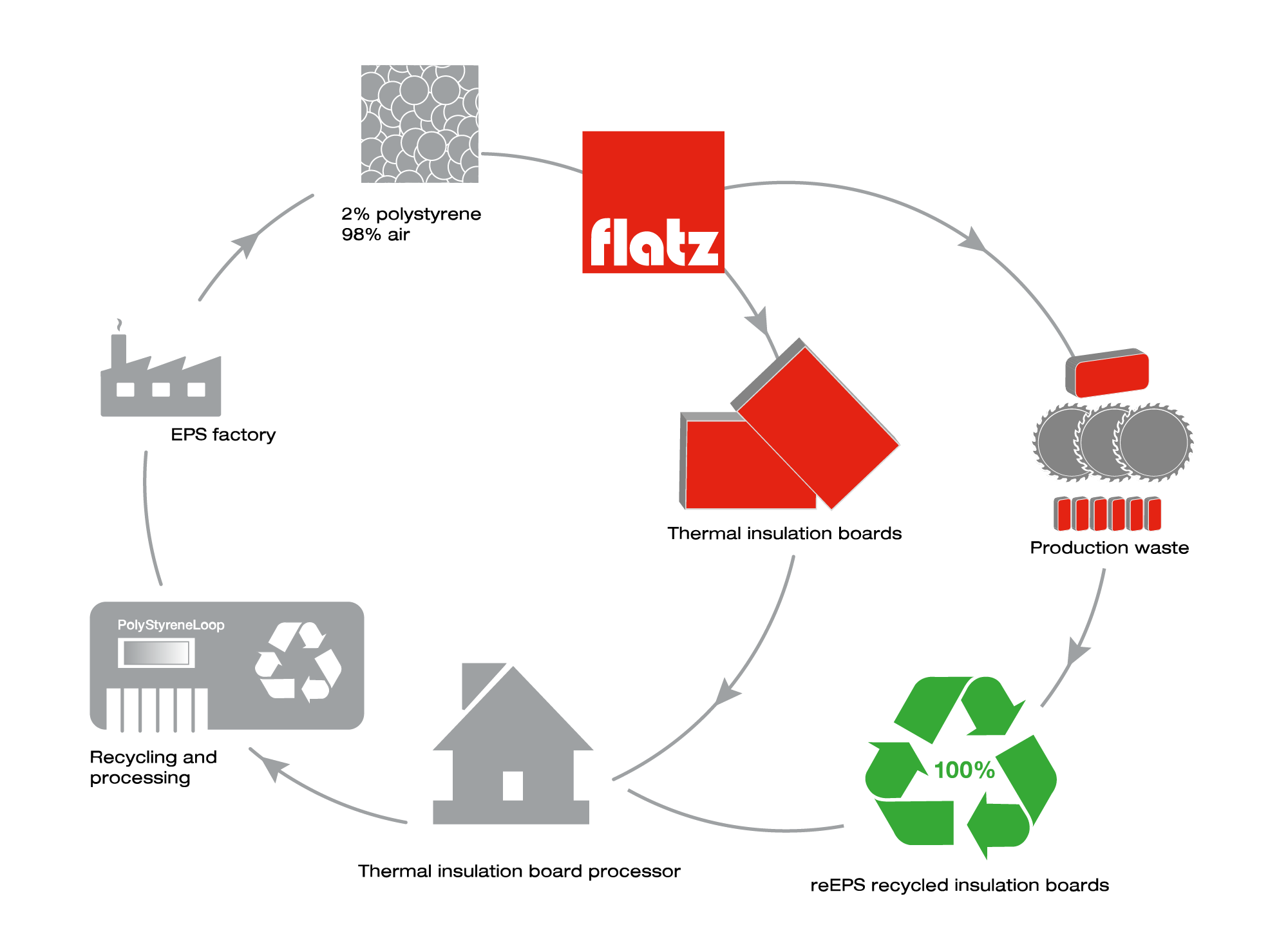

Even the process of manufacturing EPS makes very efficient use of raw materials and energy, with any waste materials being returned immediately to the production cycles and uncontaminated production waste or cuttings from construction sites being recycled. EPS waste which is ground down is used as a heat-insulating lightweight aggregate for concrete, bricks mortar and renders. It is also possible to produce recycled insulation boards. In addition, recycled EPS granules have long been used as a plant substrate and soil additive for drainage, loosening the soil and composting.

Used EPS can be cleanly disposed of in modern waste incineration plants. Its calorific value means that it replaces the auxiliary firing that is otherwise needed. If incineration is not possible, EPS can easily be deposited alongside normal household waste at proper landfill sites. It does not release any harmful substances into the air, soil or groundwater.

As well as processing it to make new packaging, Flatz also utilizes other options to fully recycle EPS material up to 10 times:

So a fully closed material cycle for managing EPS is a real thing.

The possibilities for reusing expanded polystyrene (EPS), extruded polystyrene (XPS) and compact polystyrene (PS) are unrivaled. A method developed in Canada is capable of removing impurities, but also dyes, odors, graphite and in particular HBCD from the used EPS. The Canadian technology pioneers are planning eight plants, each with an output of from 20,000 to 30,000 tonnes per year in Europe.

In Terneuzen (Netherlands), a demonstration facility was constructed in 2019 which processes not only contaminated construction site waste containing render adhesions, for example, but also used EPS with the flame retardant HBCD. The valuable bromine contained in the HBCD is recovered and reused. This recycling concept also helps to produce a complete recycling economy and is set to be introduced in other countries.

The first technologies for separating composite materials are already available. For example, “Powerbrush” is used to separate flat roof boards and bitumen sheeting.

Two technologies have since been developed to optimize the transport of used EPS to the recycling plant. Firstly, they offer the option to press polystyrene briquettes from the foams, secondly the foams can be dissolved on site and the solution can be transported to a factory. The collection and storage of polystyrene waste materials has already begun; by the time production starts, 500 tonnes of polystyrene should be in storage. This 100% recyclability makes EPS even more of an insulation material of the future.

You can obtain more detailed technical information about the new recycling methods at:

Truth:

Insulate with air! Yes, it's true that oil is the main source material for EPS. But only a very small amount of raw material is required to manufacture it. For example, the (non-renewable) primary energy content of 1 m3 of EPS for facade insulation is 435 kWh, whereas that of cork for equivalent facade insulation is 720 kWh (source: IBO). Why is this the case? EPS comprises 98% air and 2% polystyrene, the cellular structure. So EPS is full of our world’s most natural substance - air.

Truth:

Open the windows! Experts agree that almost no exchange of air takes place between the inside air and outside air through an outside wall which is designed properly and does not have any cracks or gaps in it. From this point of view, there is no difference between walls made of building materials such as wood and bricks or walls made of concrete and steel. The exchange of the air inside rooms that is required takes place by ventilation through windows or special ventilation equipment. Walls do not breathe! The water vapor diffusion resistance of EPS is the same as that of wood.

Truth:

Breathe easily: During the production of EPS, polystyrene beads containing blowing agent are heated up with steam and expanded up to 50 times their original volume. The blowing agent used is a hydrocarbon with a low boiling point (pentane) which also occurs naturally in many places. Pentane is not one of the greenhouse gases and therefore also does not damage the ozone layer in the stratosphere. Chlorofluorocarbons (CFCs) or HCFCs have never been used for producing EPS. So with EPS nobody needs to worry about the air they breathe.

Truth:

Whole colonies of bees demonstrate that EPS is harmless. EPS is used as a material for beehives (known as hives). The bees populate the hive evenly right up to the EPS walls and feel very much at home throughout. They start producing honey earlier, which is an indication of greater vitality and better health. The instinct of sensitive bees would never allow them to settle in unhealthy surroundings. Bees instinctively act the right way. They know what is good for them.

Truth:

Good for the soil: EPS is extremely long-lasting. It does not rot, decay or go moldy. If it does still end up at a landfill site as rubbish or construction waste, EPS has an extremely positive effect. EPS creates good aeration and therefore speeds up the rate at which the rest of the waste material breaks down. EPS is groundwater-neutral and has been a permitted material for loosening the soil for decades.

Despite this, EPS should not end up in the rubbish because the option to reuse all the material with the smallest input of energy is the best alternative from an ecological point of view.

Truth:

It’s all about CO: Numerous studies on the hazardous nature of combustion gases have shown that the toxicity almost always derives from carbon monoxide (CO) and that the concentration of CO is lower in the combustion gases of EPS than it is with natural building materials such as wood or cork. The biggest advantage of EPS in the event of a fire is the extremely low fire load (98% air). The other components in the combustion gases of EPS are therefore toxicologically insignificant in the concentrations which are calculated.

What matters in this context is that EPS is “flame retardant” and can therefore never be the cause if a fire occurs.

Truth:

Bon appetit! If EPS were even in the slightest way harmful to health, would the Health Ministries and Food Authorities in Europe and around the world allow food to be packaged and transported directly in EPS? Whether it’s specialty ice cream, cakes, meat or fish – they are all packaged in EPS. EPS is authorized for use with food – is there any other insulation material that meets these requirements?

Hängt von den Anforderungen ab: Isolierend mit Transportschutz, Mehrweg mit einfachem Handling, hoher Transportschutz und doch leicht und natürlich auch die Optik. Geht alles, fragen Sie uns einfach.